EMI gaskets provide protection to devices by preventing electromagnetic interference. They are conductive materials that create an electrically conductive path between surfaces like doors, seams, or coverings. By preventing interfering signals from entering or exiting the electronic devices and equipment, EMI gaskets help maintain and enhance their performance.

The use of EMI gaskets in a variety of industries requires deep technical knowledge, expertise, and a passion for problem-solving. Because a design that doesn’t fulfill its intended purpose may destroy the electric circuits by causing dire consequences.

The waves causing electromagnetic interference that prevent the device from working or even damage it may come from many different sources. Using silicone gaskets for EMI shielding especially within all-metal housings is recommended. These special elastomers not only respond to high shielding standards but also provide environmental sealing.

If the design utilizes EMI silicones, then the gasket fabrication process also becomes significant. Three types of processes offer different advantages for specific applications.

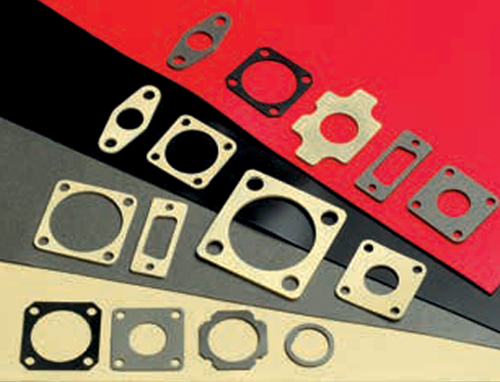

- Die-Cutting

A die-cutter equipped with a sharp-edged tool cuts out gaskets from the shielding material to a specific design or pattern. This process allows for precision and efficient production of consistent shapes, ensuring continuous accurate fit for intended applications.

Die-cutting supports nested parts, punched holes, and slots with tailored radii for fasteners. Gaskets can also include a conductive PSA backing, replacing messy liquid adhesives on assembly lines. Enabling kiss-cutting is another advantage that speeds up assembly by simplifying the removal of PSA release liners.

As these products are produced and procured from many countries, they have a lead time of 2-4 weeks.

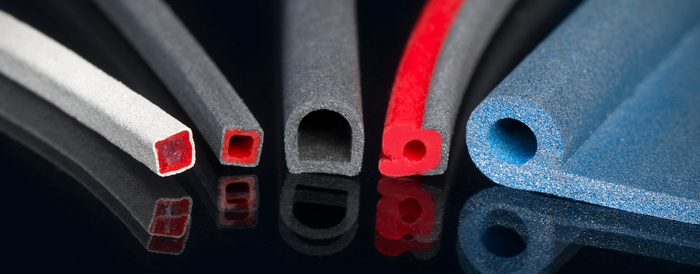

- Extruded EMI Shielding Gasket

Ideal for flange or groove applications, extruded gaskets have a range of standard or semi-standard profiles; solid O, hollow O, D, P, E, U, solid square; and hollow square. In case you need an uncommon shape, your gasket manufacturer may customize a unique gasket which may also come with anti-stretch and press-fit features.

After extrusion, the gaskets can be cut and spliced for specific designs for fully effective EMI and RFI shielding enclosure seals.

Since extrusions can be made with thin outer layers of silicone, the volume of silver or nickel graphite reduces significantly, making extrusion a great choice to use expensive RF shielding materials efficiently.

- Molded EMI Shielding Gaskets

Alternative to trying to make the gasket fit, this process offers custom molding that perfectly suits your design. This process reduces cost by eliminating the center-drop waste associated with die-cutting, requiring less material, and reserving the budget for more expensive RF shielding materials.

Molded shielding can also provide three-dimensional and intricate designs. However, this may alter the cost and elongate lead time. Based on the design, the efficient molding process can be very fast and precise, which reduces waste material and enables automation in most cases, specifically in volume applications.

As one of the leading manufacturers of EMI shielding gaskets, Nolato is a manufacturing and developing partner of high-tech polymers operating in Europe, Asia, and North America.

The headquarters -Nolato Tech Center- is located in Hallsberg, Sweden. Other manufacturing facilities are operated in Beijing, Penang, and Györ.

Nolato has ISO9001 and ISO14000 certificates for quality management systems and the MIL-DTL-83528 certificate for specific product families.

Developing and manufacturing catalog and custom design products in a variety of areas such as medical, telecommunication, industrial, automotive, and security, Nolato has product families that can respond to these manufacturing processes.

Provides optimal MIP (molecularly imprinted polymer) materials as well as design and expertise.

Nolato’s extruded gaskets are used in defence, automotive, and telecommunication applications.

For more information and product catalog: