Underwater connectors are highly complex fundamental components for deep-sea engineering, equipment, and structures. Examples of various application areas include remotely operated manned and unmanned underwater vehicles (ROVs) like submarines, large oil and gas pipelines, underwater communication, and subsea navigation.

Due to harsh conditions such as high pressure, currents, and extremely low temperatures, underwater connectors are designed to be more complex compared to standard connectors. Generally, they can be categorized into two types based on their ability to mate and demate: wet and dry connectors.

Wet-Mateable Connectors (WMCs)

Wet-mateable connectors are a group of connectors that can be both connected and disconnected while underwater. As a safety precaution, these operations can only be performed when the power is cut off.

They have a more complex structure to prevent water leakage during connection and disconnection, ensuring the safety of electronic or optical systems and the operator. These connectors are designed and manufactured to withstand high pressure, using rubber material and a single-body structure with plastic injection molding.

These connectors can reduce the time and cost of Total Productive Maintenance (TPM). They offer an effective solution for expanding and maintaining underwater systems. Additionally, they are connectors that require the highest technologies in their field and are produced in only a few countries worldwide.

Dry-Mateable Connectors: DMCs

Dry-mateable connectors, which have a different design, can only be connected and disconnected in a dry environment. Therefore, they have a simpler structure and are considered safer. Once connected, they remain watertight underwater.

Thanks to their metal primary material, they have a stronger structure. Despite the use of metal, their special design prevents them from being negatively affected by high pressure, rust, and temperature changes.

Unlike wet-mateable connectors, which need to be lubricated before installation, dry-mateable connectors require less maintenance and are easier to store.

Regardless of the area of usage, there are many advantages to having a variety of options for underwater operations.

Underwater environments vary significantly in terms of factors such as depth, pressure, temperature, salt percentage, and even water pollution. Therefore, it is critical to use connectors made from materials suited to the environmental conditions.

Wet-mateable connectors are preferred for dynamic operations depending on the start and execution process of operations, while dry-mateable connectors can be used for stable, long-term systems.

Connector variety, especially in operations such as defense, oil and gas exploration, pipeline maintenance, and scientific research, ensures safety and successful operation. Additionally, selecting the right connector for the operation enables long-term operation and reduces costs.

Hydro designs, manufactures, and tests connector and cable solutions for all types of data transmission (signal, power, RF, optical, and hybrid) that can be required in challenging underwater applications.

To keep up with technological advancements in underwater projects, Hydro develops unique connection solutions with 40 years of industry experience and expert engineers.

Hydro connectors are extensively tested for performance and durability by third-party testing laboratories. Its standard products have successfully passed pressure tests of 10,000 PSI / 6860 MSW / 689 BAR. For higher strength requirements, Hydro also offers custom design solutions.

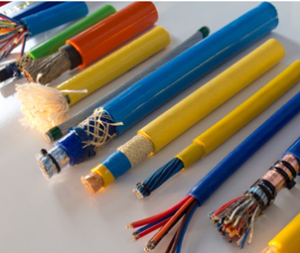

In its 52,000 square-meter production facility, Hydro manufactures underwater electrical cables, fiber optic underwater cables, hybrid underwater cables, tether cables, and underwater umbilical cables, as well as over 6,000 unique cable designs. Hydro’s underwater cables stand out with their high tensile strength, excellent insulation properties, and long-lasting materials. These cables protect against electromagnetic interference, enhancing reliability in data transmission and minimizing energy losses.

Hydro Defense Industry specializes in the custom design and production of cables for underwater and surface applications. They customize underwater cables according to project needs, providing innovative and reliable solutions. Hydro Group offers deep-sea technology in local and international projects with its catalog and custom-made connectors.

With its experience in connector design and production for underwater and surface applications, Hydro Group has been connecting deep seas with technology for many years through both catalog and custom connector designs in local, national, and international projects.

For Hydro Group product catalog:

https://www.saca.com.tr/vendor/hydro-group/